Design and manufacturing processes

3D printing has taken on an important role in medical technology, as it enables complex anatomical structures and components for medical devices to be produced quickly and precisely. One example of the use of 3D printing in medical technology is the production of patient-specific orthoses that are perfectly customised to the patient's individual anatomy. Anatomical prints can also help with the customisation of implants. The research group is also investigating other manufacturing processes such as silicone moulding for the production of phantoms for the validation of image-guided navigation procedures.

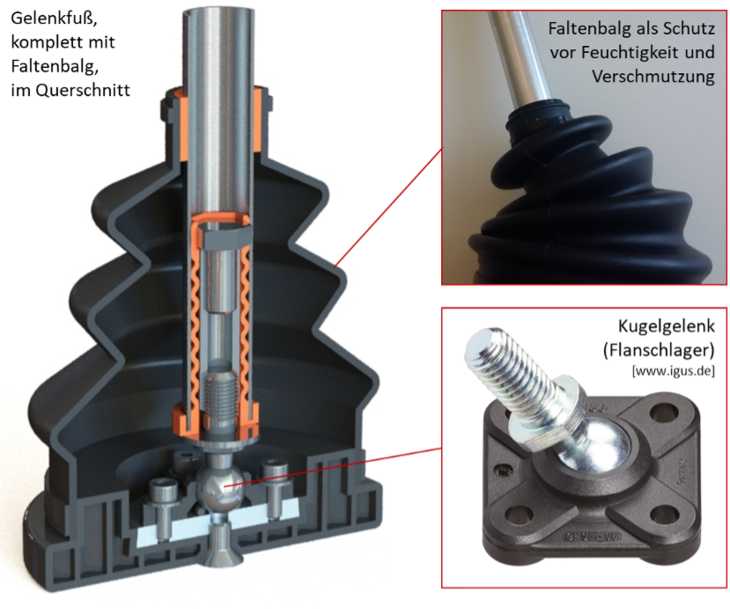

Jointed foot for crutches

Patients who are dependent on crutches for life need a secure footing even on uneven surfaces. The crutch tip, which connects the crutch to the ground, plays a crucial role in this. Conventional solutions are not suitable for everyone. A special jointed foot has been developed for one patient, which orthopedic technicians can manufacture themselves.

A 35-year-old patient with spastic tetraparesis is dependent on crutches for life (Fig. 1). He lives in a rural area where he is confronted with uneven, wet, and slippery terrain on a daily basis. Until now, the patient has been using commercially available crutch tips with four rubber feet designed for outdoor activities. In practice, however, this solution proved unsuitable:

- Insufficient contact surface: Due to spastic changes in gait mechanics, often only two of the four rubber feet are in contact with the floor. This uneven weight distribution significantly reduces stability.

- Material fatigue and breakage: The rubber feet are weakened by dynamic bending stresses. On average, they fail after six months. There have already been several cases of sudden breakage and dangerous falls.

- Health risks: Every fall carries the risk of fractures or traumatic brain injury. In addition, patients become increasingly fearful of the next accident, which leads to uncertainty when walking and limited mobility.

- Economic inefficiency: Although the end pieces only cost €30–38 in stores, the follow-up costs add up due to frequent replacements and adjustments. In addition, health insurance companies refuse to cover the regular replacements.

To solve these problems, Landshut University of Applied Sciences developed an end piece based on a commercially available ball joint (flange bearing) (Fig. 2). The flange bearing is screwed to a base plate. This allows different plates to be used in terms of color, material, geometry, elasticity, or profiling.

Although articulated feet for walking aids have been known from patents since at least the 1980s, they are not commercially available. In the new development, care was therefore taken to use as many off-the-shelf and standard parts as possible, supplemented by a few individual parts that can be manufactured using additive manufacturing (3D printing). This makes production by orthopedic technicians economically feasible. In addition, long-term supply security can be guaranteed.

New crutches with articulated ends were made for the patient (Fig. 3). Even when first used, there was a noticeable improvement in support. The articulated foot nestles evenly against the surface. Gait analysis confirmed what the patient immediately felt: greater stability, less uncertainty, and a secure step on any surface. The patient himself describes the treatment as a turning point in his life. After years of painful falls, he feels for the first time that he can really rely on his walking aids. The fear of the next accident has given way to a new sense of security that he feels with every step. Since the change, he has remained fall-free, and the articulated feet have shown no signs of wear and tear so far.

The articulated foot was developed in collaboration between Landshut University of Applied Sciences and the Ober medical supply store in Lindenberg:

- Prof. Dr.-Ing. Raimund Kreis teaches design and development as well as technical mechanics at Landshut University of Applied Sciences.

- Prof. Dr.-Ing. Norbert Babel heads the Additive Manufacturing Laboratory at Landshut University of Applied Sciences. He is the program director for the “Additive Manufacturing – Materials, Development, and Lightweight Construction” degree program. His areas of expertise are CAD, reverse engineering, additive manufacturing, and design.

- Peter Roidner is a laboratory engineer and lecturer in the Faculty of Mechanical Engineering and Construction at Landshut University of Applied Sciences.

- Dietmar H. Forster is a master orthopedic technician and master orthopedic shoemaker at the medical supply store Orthopädie OBER Schuh und Technik e. K. in Lindenberg im Allgäu.

Image credits: Dietmar H. Forster (Abb. 1 & Abb. 3), Hochschule Landshut (Abb. 2)

Development of additively manufactured foot lifter orthoses

Contact person: Prof. Dr R. Kreis

Bachelor thesis Jasmin Franziska Steinherr (2025)

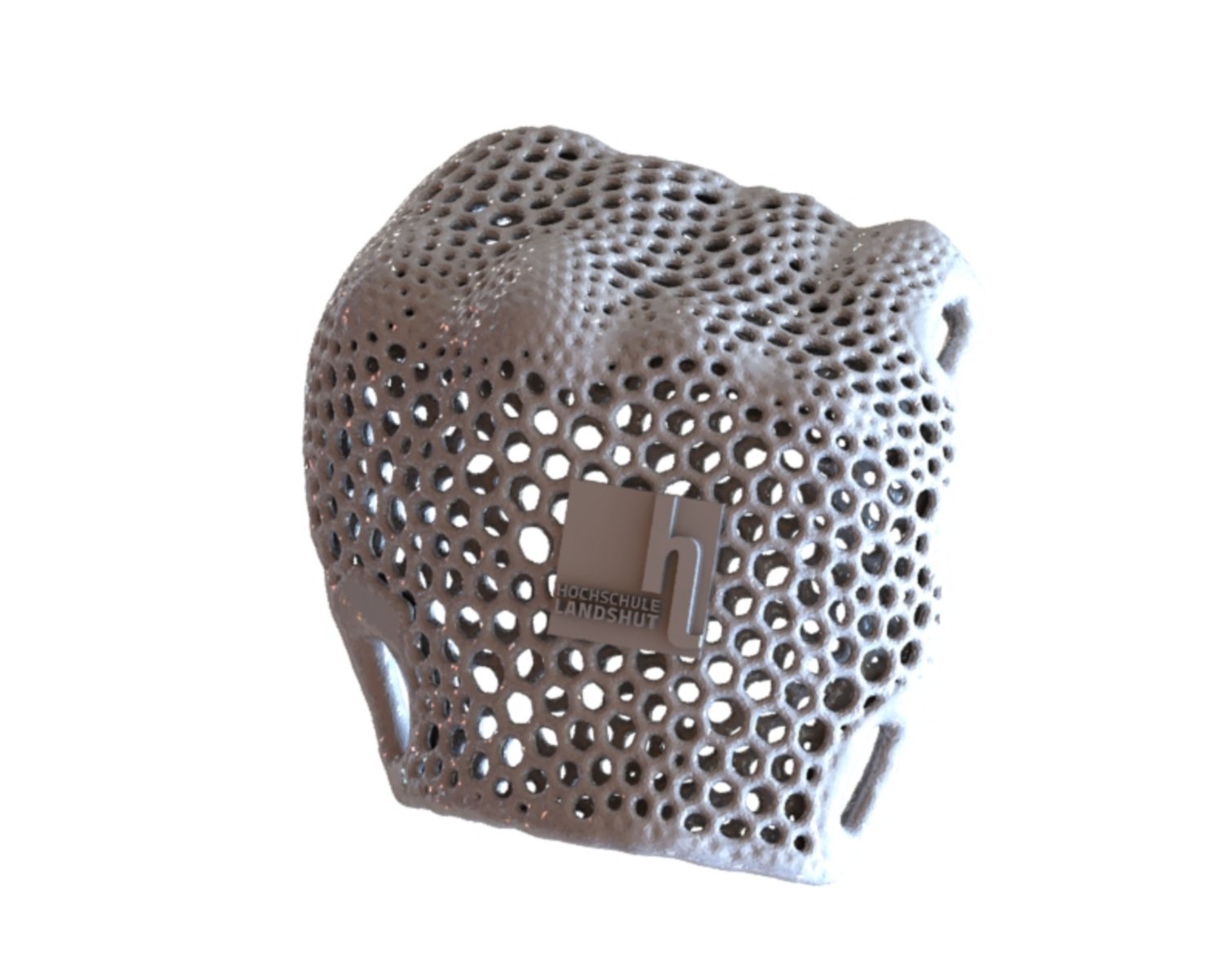

Customised facial orthoses for basketball players

Contact: Prof Dr R. Kreis

Bachelor thesis Nick Willing (2025)

Cost-effective, customised finger prostheses

Contact: Prof Dr R. Kreis

Bachelor thesis Johanna Laura Diener (2025)

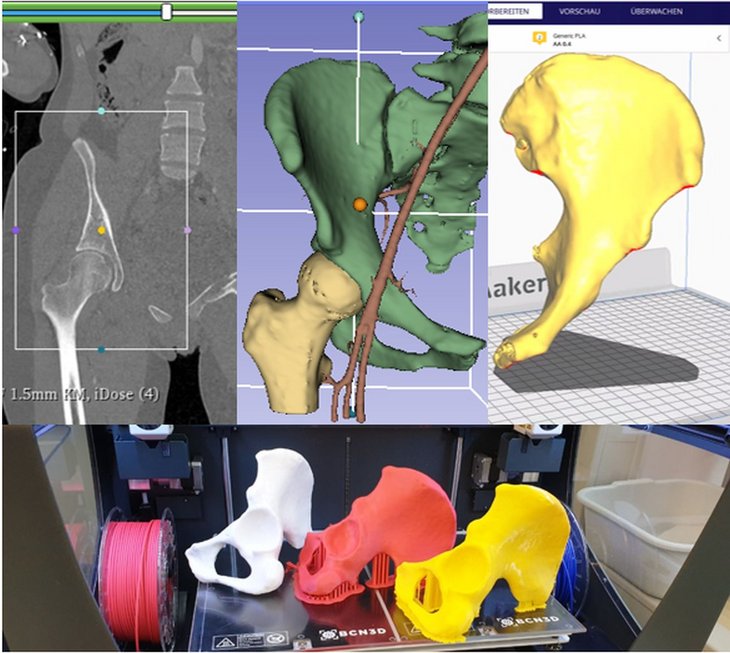

3D printing for orthopaedic surgery

Contact: Prof. Dr N. Babel, Prof. Dr S. Remmele

Partner: Dr Helmut Ersch, Orthopaedics, Agatharied Hospital

Bachelor's thesis Edith Gramotke (2021)

Various methods are currently being researched in medical technology to preoperatively adapt implants to the anatomy either on virtual bone structures or by means of 3D-printed models.

In the project, a process was developed to generate patient-specific 3D prints on which implant adjustments can be made preoperatively. Planning before the operation shortens the operation time, as the implant shape no longer needs to be optimised several times during the operation. This means less blood loss for the patient and therefore a faster recovery and a shorter hospital stay. Both the process for segmenting the CT data and for 3D printing have been optimised and evaluated in collaboration with Agatharied Hospital. To date, several operations have already been planned in this way, saving around 45 minutes of operating time according to the doctors. Edith Gramotke and Landshut University of Applied Sciences were awarded the Innovation Prize of the Scientific Society for Hospital Technology 2022(more).

Forearm crutch

Contact: Prof. Dr Norbert Babel, Prof. Dr Raimund Kreis

Project partner: Björn Furche (Ossenberg GmbH)

Bachelor theses: Veronika Selmaier (2022), Asena Kus (2023)

Walking aids such as forearm crutches in accordance with DIN EN ISO 11334-1 are often used for short periods after accidents or injuries. However, demographic change and increasing life expectancy mean that they are likely to be used for many years to come. This is because crutches can make a valuable contribution to maintaining mobility into old age. To increase acceptance, however, the walking aid must be optimally adapted to the respective user in terms of ergonomics and comfort. In addition, the image must change from that of a crutch - colloquially used to describe any form of half-baked makeshift device - to that of a stylish accessory.

The customisability of existing solutions is often still limited to length adjustability. However, a trend towards a greater variety of colours and shapes is already discernible. The aim of this project is to use additive manufacturing processes, for example, to customise forearm crutches more closely to the individual needs and wishes of the user. This concerns, for example, the geometry, colours and shapes of the crutches as well as the integration of additional functions.he company EBM Papst in Landshut over 40 Cardboard headsets!(Video)

KREIS, R. Customised forearm crutches - time and cost savings through the use of additive manufacturing [online]. 2023.(Link) [Last accessed 08.03.2023]

KREIS, R., V. SELMAIER and N. BABEL. Individualised forearm crutches. Design & Development. 2022. no. 5, p. 28-31.(link) [Last accessed 27/09/2022] .

KREIS, R., V. SELMAIER and N. BABEL. Customised production of forearm crutches using 3D printing. Management & Hospital. 2022. no. 4, p. 13.(link) [Last accessed 27.09.2022]

Opus

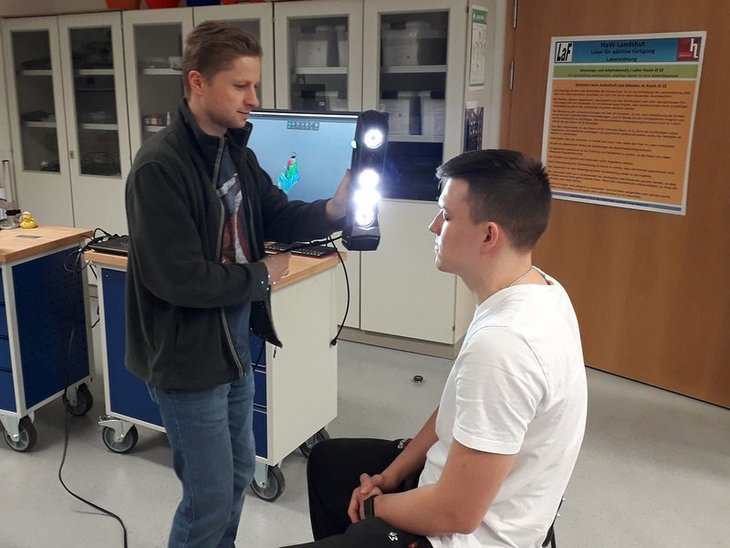

Hand orthoses

Norbert Babel, Prof. Dr.-Ing. Raimund Kreis

Project partner: Dr Helmut Ersch, Agatharied Hospital

Bachelor's thesis: Nicolas Dietz (2023)

Orthoses are often used after injuries or illnesses to support the healing process. Orthoses enclose body parts in order to relieve and/or immobilise them.

In some cases, orthoses with standard geometries are not sufficient and must be individually adapted to the patient. Moulds or plaster casts on the patient can be uncomfortable or even painful due to the physical contact and the length of time the patient has to remain in a certain position.

The aim of the project is to develop methods with which individual hand orthoses can be produced in a patient-friendly manner and with the least possible effort, possibly even directly in a medical facility. At the same time, the aim is to investigate whether CAD programmes can be used to model standard orthoses that can be 3D printed on demand.