Against a background of climate protection, emission standards and the threat of a ban on diesel vehicles, the focus of public discussion is increasingly falling on electromobility once again - and with it the aim of further developing the technology for electric cars. Landshut University of Applied Sciences is now working in collaboration with the Silver Atena company within the framework of the “Ines Selma - Integrated Electric Powertrain System with Scalable Electronics and Motor” research project to develop a new, easily manufactured and cost-effective technology for the entire electric powertrain. This is based on an electric motor with integrated power electronics, sensor and control technology and is intended, in future, to be utilised as a powertrain for electric and fuel cell vehicles, a starter generator and a drive motor in aviation. The project commences on 1 April 2019 and is expected to run until March 2022.

Modular design and cost-effective production

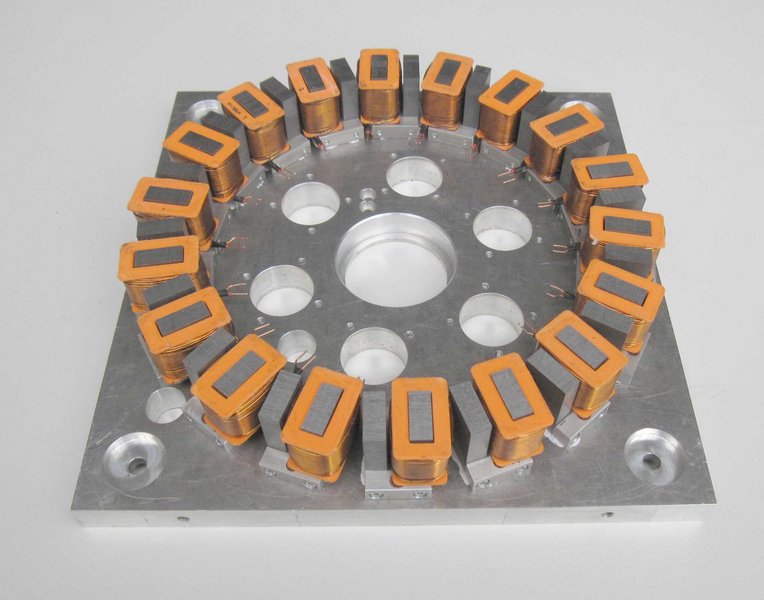

Alongside the battery and power electronics, the electric motor is the central component of every electric car. It converts electrical energy into mechanical energy, in that energised conductor coils generate magnetic fields whose mutual forces of attraction and repulsion ultimately generate torque when we step on the accelerator. The basic idea for the new electric motor concept was developed at Landshut University of Applied Sciences in the course of a research semester. The special feature of this so-called axial flux motor is its modular construction from u-shaped cores and the use of standard components such as UI30 laminations and plug-in coils.

“This makes the machine very easy to manufacture and scalable according to need - smaller vehicles simply need fewer yokes, whilst larger ones need more,” explains Professor Dr. Alexander Kleimaier, the Project Manager at Landshut University of Applied Sciences. Another advantage of the motor is that less copper and fewer magnetic materials (rare earths) are required for manufacturing, which makes production significantly cheaper than that of traditional electric motors. Over and above this, the engine itself is short-circuit proof in the event of faults affecting individual working parts, making the system more reliable and fail-safe.

Complete system or motor and electronics

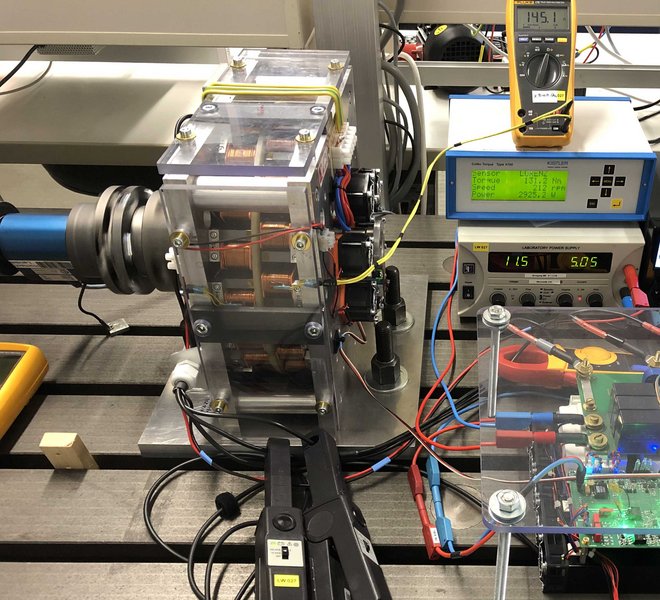

During the project, Kleimaier intends to further develop this motor from the experimental setup in the laboratory to a prototype that can be used in a vehicle. “We are currently not yet satisfied with the noise emissions,” explains Kleimaier, “and the demands on the power electronics are still too high. We still need to work on this.” Simultaneously, Silver Atena is working on these very power electronics, which control the motor, and communicate with the vehicle controls. The combination of these two components will result in a complete electric powertrain system that - in this form - optimally tailors the motor, electronics, control software and sensor technology and integrates them at system level.

Objective is applicability in vehicles

There is still a long road ahead of Kleimaier and Silver Atena before this stage is reached: “The first step is to develop both components - motor and electronics - in parallel and to harmonise them. In the second step we will combine the two, and thirdly put the unit into operation on the test bench, in order to see whether the system is also capable of being used in vehicles,” explains Kleimaier regarding the different project phases. The fourth step will involve improving those aspects that the testing shows need to be improved. “Our aim is to make it possible to utilise the new system in vehicles,” says Kleimaier. If we are successful, Landshut University of Applied Sciences will finally have established itself as a newcomer in the field of engine development. The patent application for the axial flux motor is already in the pipeline.

About the Project

The “Ines Selma - Integrated Electric Powertrain System with Scalable Electronics and Motor” project is planned to run until March 2022. The Project Manager at Landshut University of Applied Sciences is Professor Dr. Alexander Kleimaier. The project is financed by the Federal Ministry for Economic Affairs and Energy. The overall project size is around Euro 1,040,045.

Project partner: | Silver Atena Electronic Systems Engineering GmbH |

Project management: | Landshut University of Applied Sciences / Silver Atena (depending on work package) |

Landshut University of Applied Sciences Project Manager: | Prof. Dr. Alexander Kleimaier, Faculty of Electrical and Industrial Engineering |

Funding amount: | Euro 300,045 |

Overall project size: | Euro 1,040,045 |

Financing: | Bavarian Ministry of Economic Affairs, Regional Development and Energy |