What will the mobility of the future look like? This question is currently being asked by the world of science and our wider society alike. In this respect, vehicles which have fuel cells are also being discussed. These vehicles have an electric engine and generate the electrical energy required for the driving process from the combustion of hydrogen. The power electronics play a major role during this propulsion process: these are required to convert the electrical energy appropriately, for example, the direct current from the high-voltage electrical system of the vehicle into three-phase current for the electric engine. The current of the fuel cells can vary considerably according to the load. Hydrogen cars therefore require what is known as a DCDC converter, which adjusts the current for the high-voltage on-board network accordingly. The Dragan project at Landshut University of Applied Sciences is currently conducting research into a DCDC converter of this kind. Here, in contrast to previous models, gallium nitride transistors (more precisely GaN HEMTs) are being used, which allows the converter to be constructed on a particularly light and compact basis. The research team led by Prof. Dr. Alexander Kleimaier is also hoping to achieve advantages in terms of production costs and efficiency. Silver Atena is participating in the project as a business partner. The Bavarian Collaborative Research Programme for Innovative Propulsion Mobility (Bayerische Verbundforschungsprogramm Mobilität Innovative Antriebe) is supporting the project with total funding of 686,900 euros.

Key technology for the energy transition

“Power electronics are indispensable for modern mobility,” emphasizes Kleimaier, “but this technology is usually completely overlooked in the public debate.” However, it is of essential importance for everything associated with the energy transition: for electric cars or railway locomotives, for energy storage systems and for solar and wind power plants. “We require power electronics to feed energy into the mains grid, to charge batteries and to drive an electric motor,” explains the Landshut-based Professor.

An upheaval in the sector

The power semiconductor industry is currently undergoing an upheaval. “In the USA in particular, several very innovative companies have recently emerged that are conducting intensive research into further developments in this area,” explains Kleimaier. In this context, power semiconductors which are not based on the traditional silicon but on silicon carbide or gallium nitride, are now gaining ground. These place significantly higher demands on the design technology for the power electronic circuits, however. After all, to be able to use the new power semiconductors, new, innovative assembly technologies are required – a major challenge for the new project.

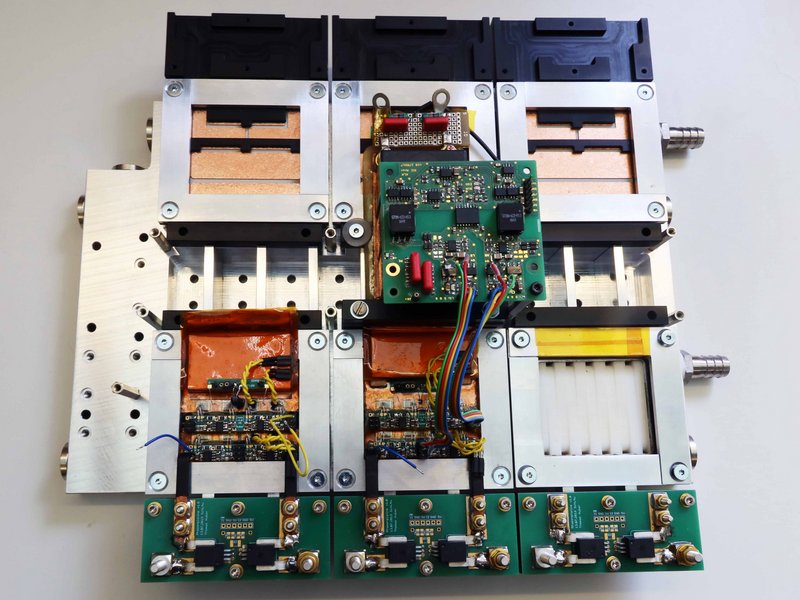

Compact, light and efficient

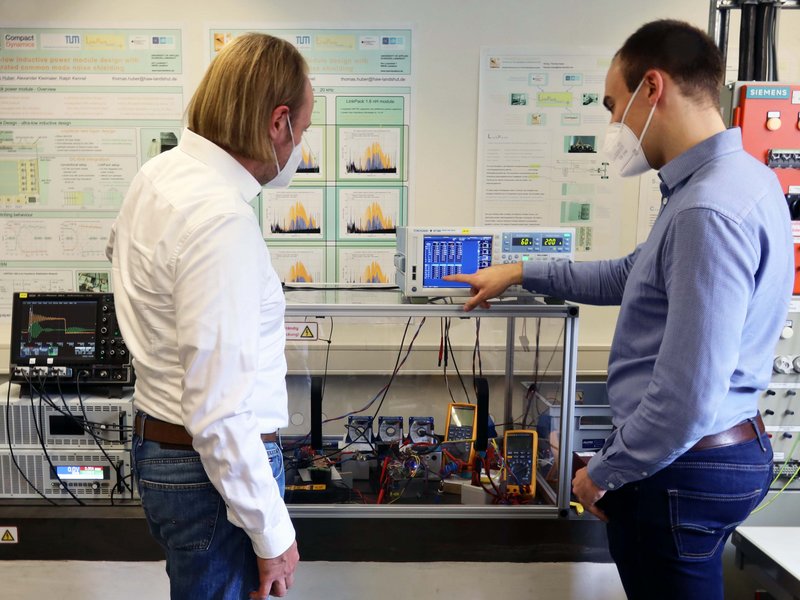

“At our laboratory for power electronics at the Faculty of Electrical and Industrial Engineering, we are working on the realisation of a particularly low-inductance assembly technology which also generates as little interference as possible,” explains Kleimaier. This would enable the team to harness the excellent properties of the new semiconductors as far as possible, and to make the power electronics much more compact and efficient. “Space requirements and weight are always problematic in vehicles and therefore need to be optimised,” explains the researcher. The scientists are also hoping for advantages in terms of costs.

The mobility of the future?

It is not yet possible to say for certain whether cars with fuel cells will become established in the future. It will ultimately be necessary to weigh up and compare both the advantages and disadvantages. Fuel cells mean that hydrogen vehicles can be refuelled more quickly and have a greater range than the current electric vehicles with batteries. Moreover, as an energy carrier, hydrogen enables large amounts of energy to be stored. “On the other hand, there are also considerable losses due to the conversion of the energy,” explains Kleimaier. “After all, firstly, we have to generate the hydrogen with the use of regenerative energies, then compress or liquefy it using energy, and then convert it back into electrical energy using fuel cells.” It goes without saying that the scientists have a lot more work to do in the future. “And finally, the findings will also have to be implemented and applied if we want to improve our CO2 footprint,” says Kleimaier.

About the project

The “Dragan - Development, Assembly and Test of 3-Level GaN Power Electronic Modules” project is running from 2020 to 2023. Prof. Dr. Alexander Kleimaier at Landshut University of Applied Sciences is responsible for the overall project management. The project partner is the company Silver Atena. The Bavarian Research Programme for Innovative Propulsion Mobility is supporting the project with total funding of 686,900 euros.

Project name: | Dragan |

Project partners: | Landshut University of Applied Sciences Silver Atena, Landshut |

Overall project management: | Prof. Dr. Alexander Kleimaier, Landshut University of Applied Sciences |

Funding of Landsut University of Applied Sciences: | 340,000 euros |

Total sum: | 686,900 euros |

Funding: | Bavarian Research Programme for Innovative Propulsion Mobility |